- Email Id :

- Call Us: :

+91-9821137386

+91-9821137386

Table Of Content

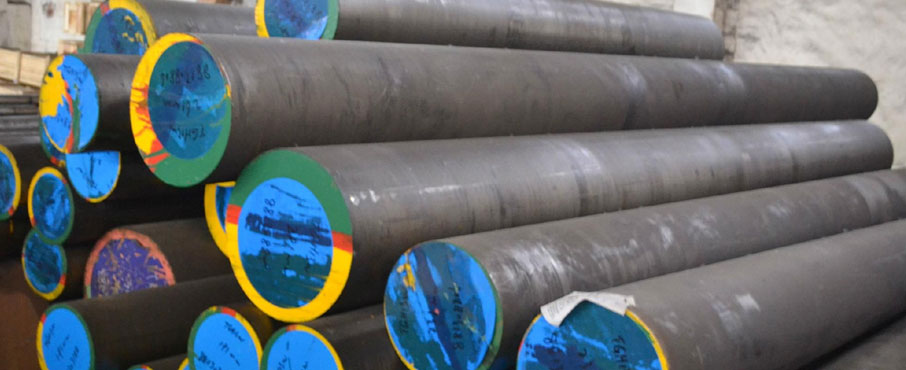

Reliant Pipe (Iso Certified ) Alloy Steel 4340 Bar Suppliers in India | Check 4340 Round Bar Price List India, 4340 bar Stockist in Mumbai, Bengaluru, Chennai, USA, UK, Houston, Dubai, Seoul, Hyderabad, Abu Dhabi,canada,singapore,Ahmedabad, Tehran,south africa,houston,Riyadh,Vadodara,London,Coimbatore,Jakarta,Istanbul,Bangkok, Kuwait City, uae, 4340 alloy steel round bar is a nickel-chromium-molybdenum alloy steel known for its toughness and its ability to attain high strengths in the heat-treated condition. It has very good fatigue resistance.

AISI 4340 alloy steel round bar Similar Grades

AISI 4340 alloy steel round bar Available Size

Heat Treatment

Annealing/Normalizing/Hardening/Tempering/Quenching

4340 alloy steel bar is used heavily in the aerospace industry due to its ultra-high strength. When heat treated it is known for its toughness while preserving good fatigue strength. For highly stressed parts it is excellent choice. It can be machined by all customary methods. This material is available in both vacuum melt (VM) and air melt (AM).

4340 ROUND BAR STOCK

Reliant Pipes is a distributor of 4340 round bar stock in cold finished form. Our team works with you to ensure you get 4340 alloy round bar that meets your exact specifications and needs.

Reliant Pipes is a mill quality producer and supplier of steel bar and wire products. Based in Mumbai (India), we have warehouse locations in seven major cities across the India. Our team is dedicated to providing quality product with excelent customer service at a competitive price.

| Minimum Properties | Tensile Strength , psi | 140,000 |

| Yield Strength, psi | 120,000 | |

| Elongation | 14% | |

| Hardness | Rc 32/39 | |

| Chemistry | Carbon( C) | .38 -.43% |

| Chrome (Cr) | 0.70- 0.90% | |

| Manganese (Mn) | 0.60-0.80% | |

| Molybdenum (Mo) | 0.20 - .30% | |

| Nickel ( Ni) | 1.65-2.0% | |

| Phosphorus (P) | 0.030% | |

| Sulphur (S) | 0.040% | |

| Silicon (Si) | 0.15- 0.35% |

4340 Alloy Steel can be heat treated to achieve high strength whilst maintaining good toughness, wear resistance and fatigue strength levels, combined with strength up to 315 ºC.

| PRODUCT FORM | SIZE RANGE FROM | SIZE RANGE TO |

|---|---|---|

| 4340 Round bar | 30 mm | 160 mm |

| % | FE | NI | CR | MN | C | MO | SI | S | P |

|---|---|---|---|---|---|---|---|---|---|

| Min | 95.195 | 1.65 | 0.70 | 0.60 | 0.37 | 0.20 | 0.15 | - | - |

| Max | 96.33 | 2 | 0.90 | 0.80 | 0.43 | 0.30 | 0.30 | 0.04 | 0.035 |

4340 Alloy Steel can be used in a variety of applications, here are just a few examples:

4340 Alloy Steel is an iron-based alloy containing nickel, chromium and molybdenum. The relatively high carbon content provides this alloy with superior strength in applications where severe service conditions exist.

4340 Alloy Steel has high strength, superior toughness and good ductility. In addition, the alloy is immune to embrittlement.

Density: 7.85 g/cm^3

Melting Range:1340-1380°C

Specific Heat Capacity:448 J/kg*K

Electrical Resistivity:1.09 µΩ.m

Coefficient of Thermal

Expansion from -18-93°C:11.3 µm/mm/°C

Coefficient of Thermal Expansion from -18-649°C:14.6 µm/mm/°C

| ROOM TEMPERATURE MECHANICAL & PHYSICAL PROPERTIES AT VARIOUS TEMPERING TEMPERATURE (NORMALISED AT 899-927 °C/AUSTENITISED AT 816-829°C/OIL QUENCHED) | 204°C | 260°C | 316°C | 427°C | 538°C | 593°C | 649°C |

|---|---|---|---|---|---|---|---|

| Ultimate Tensile Strength /MPa | 1905 | 1830 | 1140 | ||||

| 0.2% Yield Strength /MPa | 1530 | 1530 | 1035 | ||||

| Reduction of area % | 35 | 25 | 60 | ||||

| Elongation % | 11 | 8 | 18 | ||||

| Room Temperature Hardness/ Rockwell C at Various Tempering Temperature (Austenitised at 843°C/Oil Quenched/Tempered Twice for 2+2 Hours) | 52 | 47 | 41 | 35 | 25 |

| MECHANICAL & PHYSICAL PROPERTIES | 21.1°C | 100°C | 204.4°C | 315.6°C | 400°C | 537.8°C | 648.9°C | 700°C | 760°C | 815°C | 870°C | 982°C |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ultimate Tensile Strength /MPa | 792 | - | - | - | - | 726 | 473 | - | 286 | - | 139 | 66 |

| 0.2% Yield Strength /MPa | 407 | - | - | - | - | 363 | 275 | - | 152 | - | 68 | 31 |

| Reduction of area % | - | - | - | - | - | - | - | - | - | - | - | - |

| Elongation % | 31 | - | - | - | - | 27 | 32 | - | 75 | - | 90 | 91 |

| 1,000 hr Rupture Strength | - | - | - | - | - | - | 83 | 47 | 26 | 15 | 8.3 | - |

| Coefficient of Thermal Expansion /µm/m°C ** | - | 11 | 12.7 | 13.4 | 13.9 | 14.3 | 15 | 15.4 | - | 16.5 | 17.1 | 18.2 |

| Thermal Conductivity /kcal/(hr.m.°C) ** | 10.06 | - | - | - | - | - | - | - | - | - | - | - |

| Modulus of Elasticity / GPa | 221 | 216 | 210 | 203 | 197 | 190 | 181 | 173 | - | 165 | 153 | 140 |

| HARDNESS/ ROCKWELL C AT VARIOUS TESTING TEMPERATURE | 21 °C | 93°C | 204°C | 316°C | 427°C | 538°C |

|---|---|---|---|---|---|---|

| Condition A: Normalised at 899 °C for 1 hour + air cool/ Austenitised at 816 °C for 0.5 hour + oil quench/ Tempered at 246 °C for 2+2 hours +air cool | 49 | 48.5 | 48 | 45.5 | 35 | 18 |

| Condition B: Normalised at 899 °C for 1 hour + air cool/ Austenitised at 816 °C for 0.5 hour + oil quench/ Tempered at 482 °C for 2+2 hours +air cool | 40.5 | 38 | 36.5 | 34 | 31.5 | 18 |

| Condition C: Normalised at 899 °C for 1 hour + air cool/ Austenitised at 802 °C for 0.5 hour + oil quench/ Tempered at 593 °C for 2 hours +air cool | 34 | 32.5 | 30 | 27.5 | 24 | 13 |

| Title | Type/Filesize |

|---|---|

4140 W-Nr 1.7225, AS 4140, BS EN19A, AISI 4140 | Size Range: Rd 10mm - 650mm, Hollow 45/28 - 200/140mm, Other size available on request |

709M W-Nr 1.7225, AS 4140, BS EN19A, AISI 4140 | Size Range: Other sizes available on request. |

4340 W-Nr 1.6565, AS 4340, BS ~EN24, AISI 4340 | Size Range: Other sizes available on request. |

EN-25 W-Nr 1.6743, AS X9931, BS EN25 | Size Range: Other sizes available on request. |

EN26 W-Nr 1.6745, AS X9940, BS 970 826 M 40 | Size Range: Other sizes available on request. |

4145H AISI 4145H Mod.API Spec.7 | Size Range: Other sizes available on request |

SAE 4340 Chromoly steel is ideal for parts requiring critical harden-ability and high strength metal. For example, gears and aircraft parts which operate under highly stressed, severe conditions perform exceptionally when made from 4340 AQ metal. The term Aircraft Quality (AQ) steel means it is suitable for the manufacturing of aircraft parts which are subject to magnetic particle inspection after machining.

AMS 6359 - AISI 4340 (E4340) Aircraft Quality Steel Plate Size Table

| SIZE INCHES | WGT./ SQ.FT. | 18" x 72" ANNEALED | 36" x 72" ANNEALED | 72" x 144" ANNEALED |

|---|---|---|---|---|

| 0.190 | 7.945 | HR | HR | HR |

| 1/4 | 10.20 | HR | HR | HR |

| 5/16 | 12.75 | HR | HR | HR |

| 3/8 | 15.30 | HR | HR | HR |

| 1/2 | 20.40 | HR | HR | HR |

| 5/8 | 25.50 | HR | HR | HR |

| 3/4 | 30.60 | HR | HR | HR |

| 7/8 | 35.70 | HR | HR | HR |

| 1 | 40.80 | HR | HR | HR |

| 1 1/4 | 51.00 | HR | HR | HR |

| 1 1/2 | 61.20 | HR | HR | HR |

| 1 3/4 | 71.40 | HR | HR | HR |

| 2 | 81.60 | HR | HR | HR |

| 2 1/2 | 102.00 | HR | HR | HR |

| 3 | 122.40 | HR | HR | HR |

| 3 1/2 | 142.80 | HR | HR | HR |

| 4 | 163.20 | HR | HR | HR |

| 4 1/2 | 183.50 | HR | HR | HR |

| 5 | 204.00 | HR | HR | HR |

| 6 | 244.83 | HR | HR | HR |

| 4340 bar | 4340 hr ht bar |

| 4340 bar sizes | 4340 steel hex bar |

| 4340 bar ams 6414 | 4340 steel bar properties |

| 4340 bar suppliers | 4340 round bar price |

| 4340 round bar | 4340 steel bar price |

| 4340 flat bar | 4340 round bar weight |

| 4340 bar stock | 4340 round bar sizes |

| 4340 steel bar suppliers | 4340 round bar stock |

| 4340 rectangular bar | 4340 round bar specification |

| 4340 flat bar stock | 4340 steel round bar |

| 4340 aq bar | aisi 4340 round bar |

| 4340 annealed bar | 4340 square bar |

| aisi 4340 bar | 4340 square bar stock |

| a cylindrical 4340 steel bar | 4340 steel bar stock |

| 4340 chrome bar | 4340 heat treated bar |

| 4340 steel bar distributors | 4340 hollow bar |

| 4340 flat bar suppliers | 4340 hr bar |

| 4340 forged bar | 4340 round bar houston tx |

| 4340 steel bar for sale | 4340 hex bar |